Tier 4 Compliance Explained

Goal of Tier 4

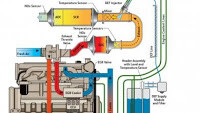

The EPA originally implemented the Tier 4 system in order to create a standard by which to regulate the emissions for “non-road diesel engines”. These include industrial equipment like skid steer loaders, mini excavators and even stationary equipment like generators. The Tier 4 standard, phased in by 2015, introduces a substantial reduction in NOx emissions above and beyond what was introduced during the Tier 1-3 initiative. They accomplished this by using their regulatory body to force engine manufacturers to invest in new technological solutions to decrease engine emissions.

The EPA originally implemented the Tier 4 system in order to create a standard by which to regulate the emissions for “non-road diesel engines”. These include industrial equipment like skid steer loaders, mini excavators and even stationary equipment like generators. The Tier 4 standard, phased in by 2015, introduces a substantial reduction in NOx emissions above and beyond what was introduced during the Tier 1-3 initiative. They accomplished this by using their regulatory body to force engine manufacturers to invest in new technological solutions to decrease engine emissions.

What it Means for Machine Owners

The good news is that if you own a machine built before these standards went into effect you don’t have to worry about Tier 4 Compliance. Replacement parts for existing engines are generally not required to meet Tier 4 regulations. However, if you need to replace your engines, vendors can only supply you with a Tier 4 compliant engine.

The good news is that if you own a machine built before these standards went into effect you don’t have to worry about Tier 4 Compliance. Replacement parts for existing engines are generally not required to meet Tier 4 regulations. However, if you need to replace your engines, vendors can only supply you with a Tier 4 compliant engine.

If you are in the market some new equipment like a new forklift or a track loader, you can expect to see a small increase (1-3%) in price and you’ll be required to use Ultra-Low Sulfur Fuel costing about 7 cents more per gallon. The use of high sulfur fuel will not only violate Tier 4 regulations, but can cause operational problems and jeopardize the component life of your new engine.

What it Means for Operators

Tier 4 compliant machines will function in nearly the same way as Tier 3 compliant machines. However, operators will notice a few new switches and dash lights relating to the engine’s Regeneration Process. The Regeneration Process heats up the engine and burns out excess carbon. This process is essential for the engine to run smoothly. Failure to perform the Regeneration Process will significantly lower the RPM of the vehicle and eventually cause it to stall out. Dash indicators will alert operators when a Regeneration is necessary and the process typically takes only 20-40 minutes to complete. It is recommended that operators familiarize themselves with these new systems and take care to only use Ultra-Low Sulfur Fuel when refueling.

Tier 4 compliant machines will function in nearly the same way as Tier 3 compliant machines. However, operators will notice a few new switches and dash lights relating to the engine’s Regeneration Process. The Regeneration Process heats up the engine and burns out excess carbon. This process is essential for the engine to run smoothly. Failure to perform the Regeneration Process will significantly lower the RPM of the vehicle and eventually cause it to stall out. Dash indicators will alert operators when a Regeneration is necessary and the process typically takes only 20-40 minutes to complete. It is recommended that operators familiarize themselves with these new systems and take care to only use Ultra-Low Sulfur Fuel when refueling.

Benefits of Tier 4 Compliance

Environmental Impact

Once all applicable vehicles are equipped with Tier 4 compliant engines, 739,000 tons of NOx and 129,000 tons of PM will be eliminated from our environment annually. This would be similar to the environmental impact of removing over 25 million passenger cars from American roads. It is estimated that by 2030, these standards will prevent 12,000 premature deaths every year.